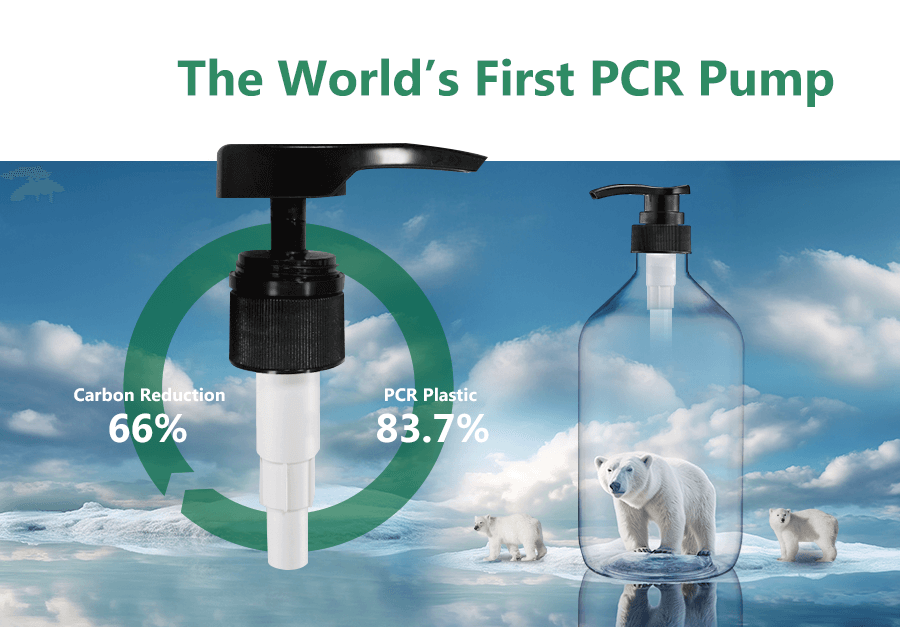

The world's first PCR pump

Living Fountain, in collaboration with the beauty brand O'right, has successfully developed and manufactured the world's first PCR(Post-Consumer Recycled) dispensing pump.

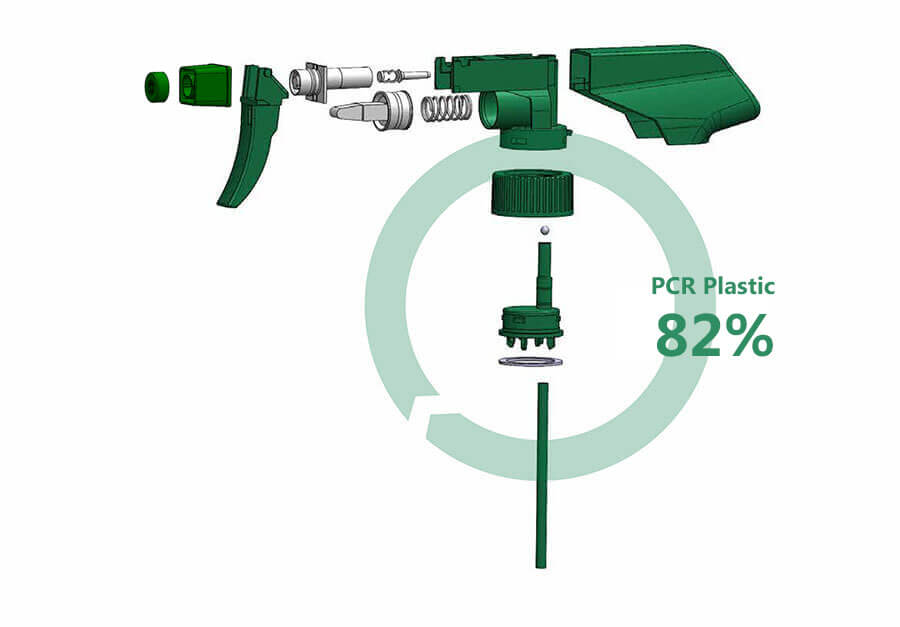

The construction of the dispensing pump proved to be much more complex than anticipated, especially considering that, take O'right's shampoo as an example, a seemingly ordinary dispensing pump consists of as many as 11 internal components.

When the order came in from O'right in 2016, Chairman Chan Ching-Chung of Living Fountain admitted, "To be honest, we were initially perplexed because we had no experience in manufacturing PCR plastic packaging. However, we had to do it; small and medium-sized enterprises cannot fear challenges."

Throughout the design and development process, the 11 components underwent rigorous testing with continuous parameter adjustments. Each part required at least 4 hours of testing, followed by a 48-hour observation period, and success was not achieved after just one attempt. Living Fountain spent nearly a year repeatedly conducting tests and inspections.

Initially, the characteristics, strength, and airtightness of PCR plastic required undergo precise testing multiple times. Consideration was also given to the plastic's elasticity, resilience, and stretchability to achieve a high proportion of PCR plastic in the dispensing pump. These steps involved repeated testing and verification for each component, requiring constant adjustments and corrections to overcome manufacturing bottlenecks. There was never a thought of giving up, as Chairman Chan Ching-Chung emphasized, "At that time, it was a commitment—never let down those who entrusted us."

In June 2018, overcoming the complexities of component composition, the development of the PCR dispensing pump was successful. With over 80% PCR plastic usage, it reduces carbon emissions by 66% compared to traditional dispensing pump made from new materials, creating a unique selling point for plastic dispensing pump.

As of June 2025, Living Fountain has produced over 3.1 million PCR dispensing pump, achieving a carbon reduction of 106,000 kg.