Energy Saving and Carbon Reduction

The traditional hydraulic injection molding machine is driven by commercial electricity (220V / 60Hz) to power three-phase induction motors, using a quantitative pump for oil supply. Due to the continuous operation of the three-phase induction motor and the action of the relief valve, energy consumption is generated. By adopting fully electric injection molding machines, not only can the original production capacity be increased, but power consumption can also be reduced to 0.435 times of the original, achieving a 56.5% energy saving.

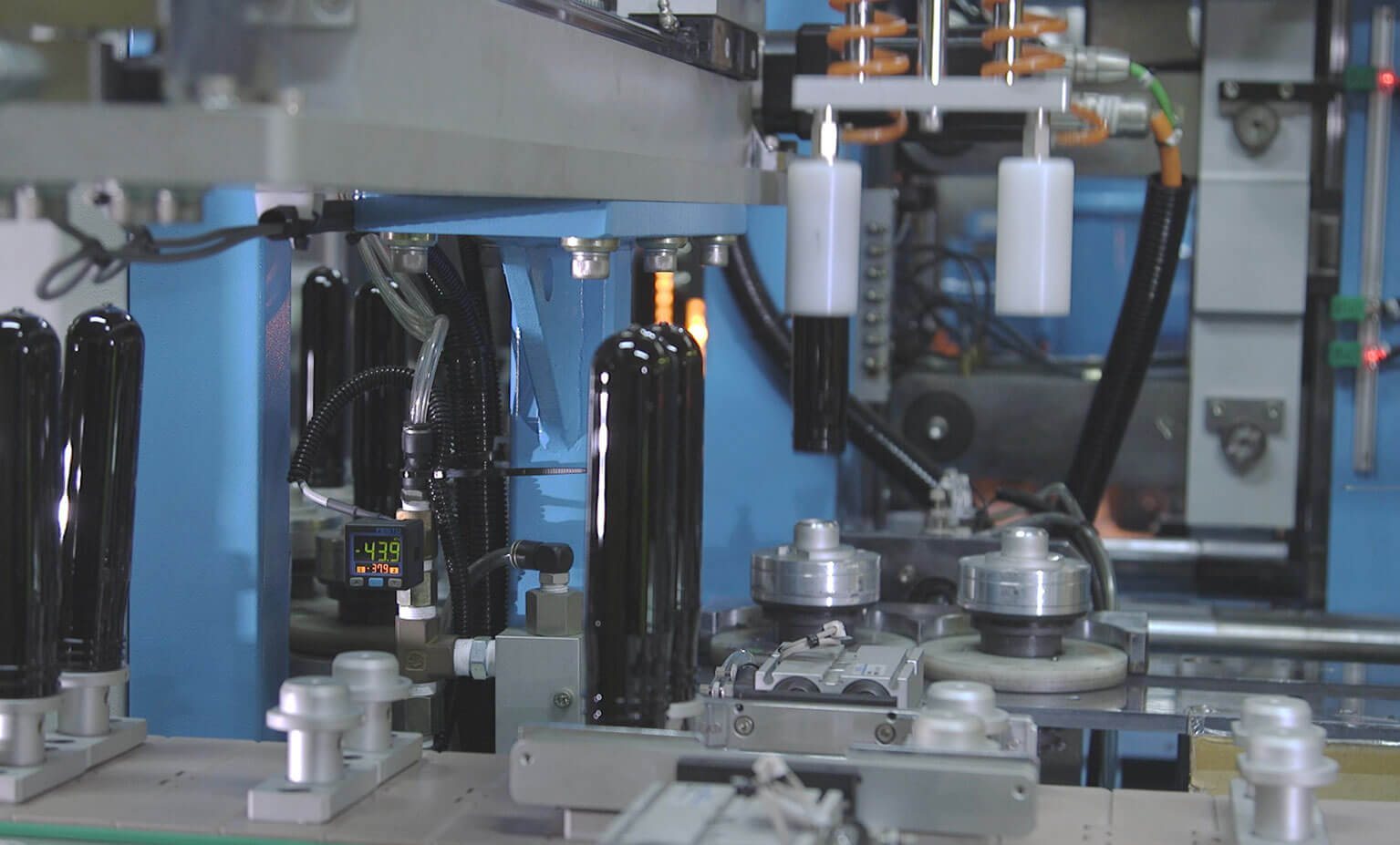

Living Fountain Company has been gradually replacing traditional machines with fully electric injection molding machines since 2015. As of 2020, a total of 11 machines have been replaced.