From Taiwan's Carbon Fee to the EU’s CBAM: How Living Fountain Builds Sustainable Competitiveness with PCR Pumps & Trigger Sprayers

As global supply chains accelerate toward net-zero emissions, countries are implementing carbon pricing and border adjustment mechanisms one after another.

Taiwan will enter its carbon-fee trial reporting phase in 2025 and officially begin fee collection in 2026 (based on 2025 emissions, payable before May 2026). The European Union will also implement full CBAM (Carbon Border Adjustment Mechanism) charges starting in 2026.

.png)

Although plastic packaging is not included in the first wave of CBAM chargeable items, international brands and buyers now place significantly greater emphasis on carbon-emission transparency and recycled-material content.

As a manufacturer with more than 30 years of OEM/ODM experience in plastic packaging, Living Fountain has long been advancing its development of PCR (Post-Consumer Recycled) packaging, carbon-reduction technologies, and sustainable supply-chain capability.

This article will help you quickly understand:

- What is Taiwan's carbon-fee system?

- Will the EU's CBAM affect plastic packaging?

- Why PCR dispensing pumps and PCR trigger sprayers are becoming key advantages for export and ESG compliance

- How brands and procurement teams can future-proof their sustainability strategy

1. Taiwan's Carbon Fee Begins: The First Carbon-Pricing System for Manufacturers (Starting 2025)

Taiwan's carbon-fee system takes effect on January 1, 2025. The government has designated 2025 as a trial reporting year, meaning no fee payments for that year. Companies must report their full-year 2025 emissions and complete their first payment before May 2026.

1.1 Fee Rate (subject to final official announcement)

- Standard rate: NT$300 per metric ton of CO₂e

- Preferential rates (for entities meeting reduction criteria):

- Category A (sector-based reduction targets): NT$50/ton CO₂e

- Category B (technology-based reduction standards): NT$100/ton CO₂e

Note: Final eligibility for preferential rates will follow official regulations and review procedures.

1.2 Who will be charged?

Large emitters with annual emissions ≥ 25,000 tons CO₂e. (Mainly power generation, gas, and certain manufacturing sectors.)

Most small- and medium-sized plastic injection manufacturers will not be charged initially. However, future adjustments, capacity expansion, or changes in energy structure may lead to inclusion.

1.3 Payment Timeline

- 2025: Trial reporting only

- 2026: Pay fees based on 2025 emissions (deadline: May 2026)

What this means for the plastic-packaging industry

Even without direct charges today, international brands increasingly demand:

- Manufacturing energy-usage data

- PCR material usage percentage

- LCA (Life Cycle Assessment) / Carbon Footprint data

Suppliers with low-carbon materials and traceable emissions will gain stronger competitiveness.

2. EU CBAM: Plastics Not Included Yet, but Regulatory Risks Are Rising

CBAM is the world's first system applying carbon cost to imported goods to ensure equal carbon pricing with EU-produced products.

Two Phases of CBAM

- Transition phase (2023–2025): Reporting only, no certificate purchases required

- Full charge phase (from 2026): Importers must purchase CBAM certificates to cover embedded emissions

Currently covered industries: Steel, Aluminum, Cement, Fertilizers, Hydrogen, Electricity, and other high-emission sectors. Plastic packaging is not yet included.

However, the EU has publicly stated it is reviewing expansion to additional downstream products by 2030, with plastics and chemicals under discussion.

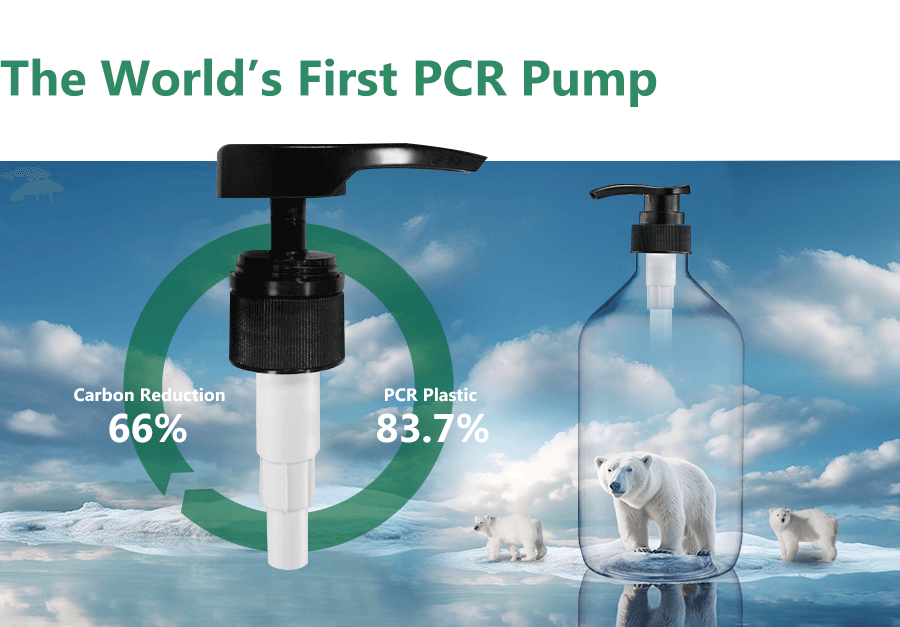

3. Living Fountain's PCR Pumps & Trigger Sprayers: Building Sustainability Competitiveness for Brands

As carbon regulations tighten worldwide—from Taiwan's carbon fee to the EU's CBAM and strict corporate ESG requirements—packaging is no longer just a cost factor.

It has become part of the core brand sustainability value.

Living Fountain has invested for years in recycled-material technologies and successfully launched PCR Dispensing Pumps and PCR Trigger Sprayers with over 80% PCR plastic usage, enabling brands to significantly increase recycled material usage without compromising functionality.

3.1 PCR Pumps — High PCR plastic usage for Material-Level Carbon Reduction

Living Fountain’s PCR dispensing pumps incorporate PCR in multiple components, achieving 80%+ PCR usage while maintaining:

- Stable appearance

- Smooth actuation and rebound

- Consistent durability and performance

Why PCR reduces emissions: Understanding Embedded Emissions

Embedded emissions = carbon emissions embodied in a material from extraction → manufacturing → transportation.

These emissions become part of your product’s carbon footprint.

PCR significantly reduces embedded emissions because it:

- Avoids petrochemical extraction

- Avoids virgin-plastic polymerization

- Only requires cleaning → sorting → re-pelletizing

Thus, PCR has a much lower carbon footprint than virgin plastic.

To ensure stability, some internal precision components remain virgin material—achieving an optimal balance between sustainability and functionality.

Applications: Personal-care, household, beauty, hygiene packaging

PCR pumps can seamlessly replace traditional pumps.

3.2 PCR Trigger Sprayers — Large-Surface Components with Low-Carbon Advantage

Trigger sprayers have more complex structures.

Living Fountain leverages decades of injection-molding experience to produce high-PCR trigger sprayers with reliable performance:

- Major external components made with PCR plastic

- Optimized atomization, Outflow per stroke, actuation, and locking strength

- Suitable for cleaners, home-care products, and large-volume packaging

3.3 Sustainability Benefits for Brands

Whether using PCR dispensing pumps or PCR trigger sprayers, brands gain:

- Lower material-level emissions (reduced product carbon footprint)

- Higher PCR plastic usage ratio (meets global procurement requirements)

- Stronger sustainability messaging (packaging, website, ESG report)

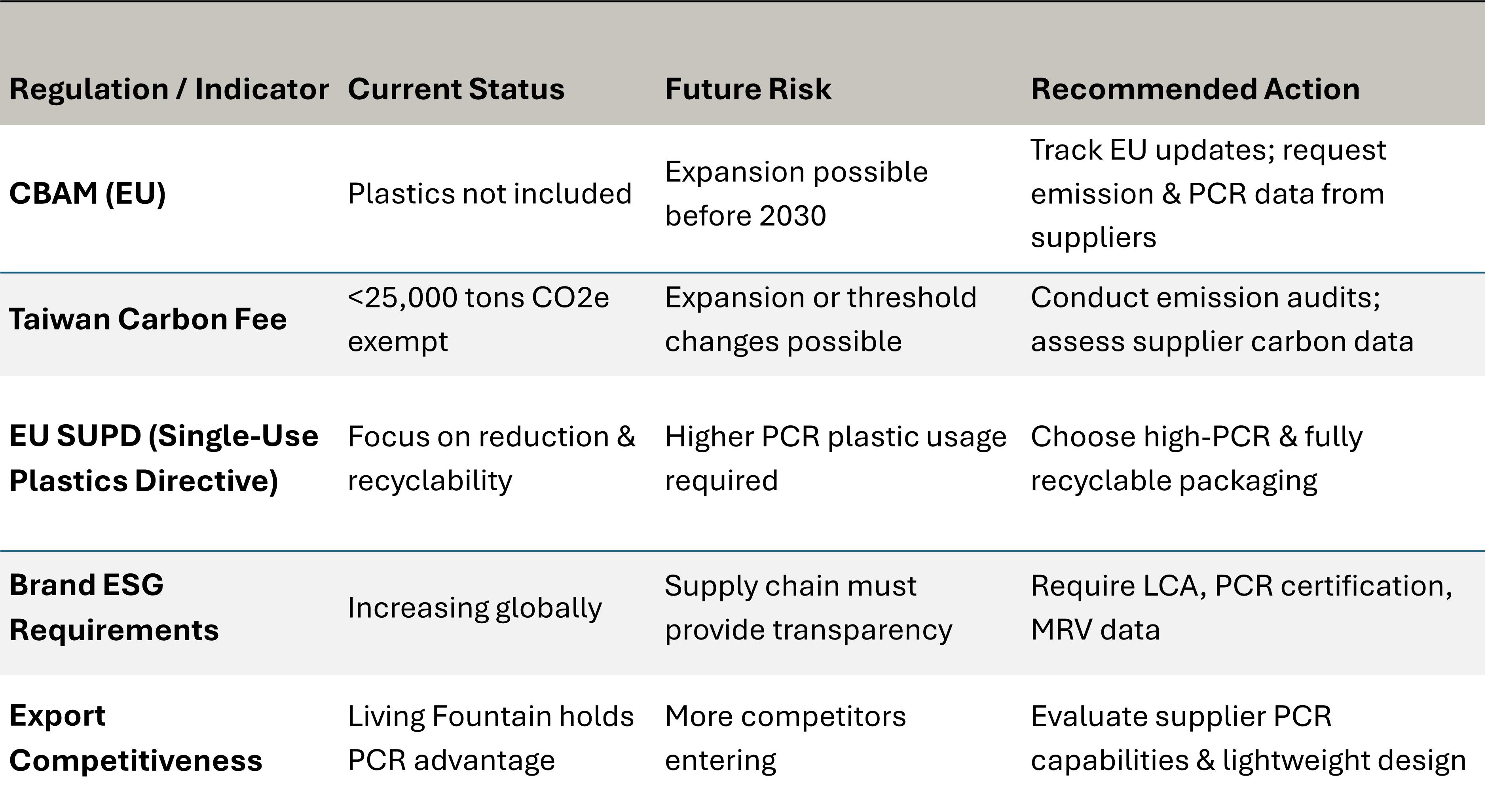

4. PCR Pumps & Trigger Sprayers for Europe — ESG & Carbon Regulation Overview (2025 Edition)

Living Fountain’s PCR solutions help brands proactively comply with CBAM, Taiwan carbon fees, and EU sustainability requirements.

5. Living Fountain’s Sustainability Commitment: A New Generation of Low-Carbon, High-Quality Packaging

With production facilities in Taiwan and Vietnam, Living Fountain has served international customers for over 30 years, specializing in:

Trigger Sprayers • Dispensing Pumps • Lotion Pumps

PCR Dispensing Pumps • PCR Trigger Sprayers • PCR PET/PP/PE Bottles

Fine Mist Sprayers • PET Bottles • PE/PP Bottles • Caps

OEM/ODM Design • Mold Development • Mass Production

We believe sustainable packaging is not only about carbon reduction— it is part of your brand value.

Preparing Early is the Best Competitive Strategy

Even though plastics are not yet included in CBAM, the global supply chain is shifting from price-driven to carbon-driven procurement. High-PCR packaging, low-carbon design, transparent material data, and carbon-footprint documentation will become essential advantages for brands between 2026–2030.

Living Fountain will continue to invest in carbon-reduction innovation and support global brands in leading both sustainability and market competitiveness.

If you are seeking low-carbon packaging, PCR solutions, or EU-compliant sustainable materials, we welcome your inquiry.