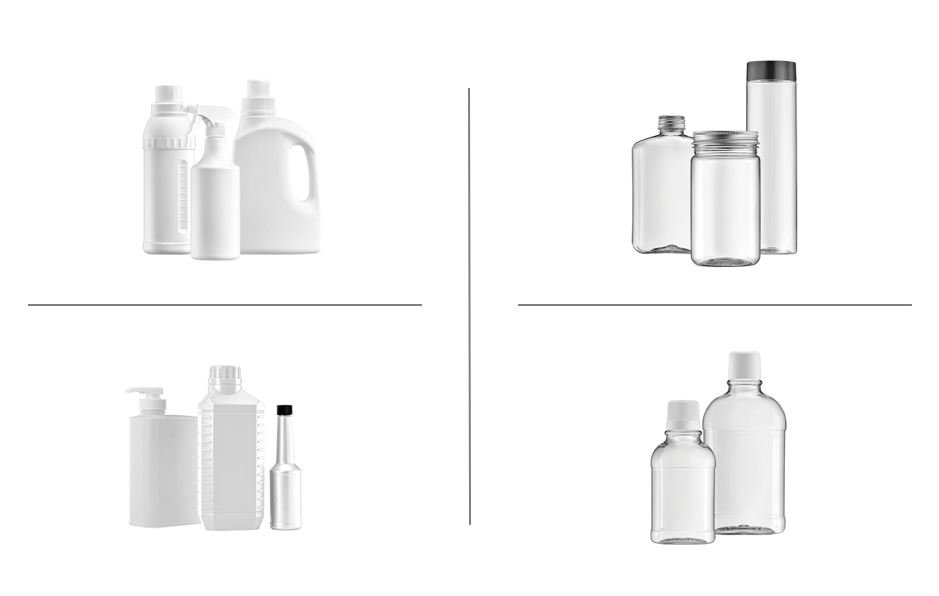

Types of Plastic Bottles and Selection Guide: What’s the Difference Between PET, PE, and PP?

Plastic bottles are virtually everywhere—in cleaning products, cosmetics, and daily life. For manufacturers, choosing the right bottle material isn’t just about looks; it also affects product preservation, safety, and user experience.

The three most common plastic bottle materials on the market are: PET (Polyethylene Terephthalate), PE (Polyethylene), and PP (Polypropylene).

What are the differences between them? And how do you choose the right one based on your product? This article will help you quickly understand the essentials!

________________________________________

🔹 1. PET (Polyethylene Terephthalate) Bottles

Characteristics:

- High transparency, appearance like glass

- Hard yet lightweight texture

- Good oil resistance

- Excellent barrier properties (effectively blocks oxygen and moisture)

Common Uses:

- Detergent bottles

- Cosmetic spray bottles

- Beverage bottles (food-grade PET)

Suitable For Packaging:

Liquid detergents, toner, alcohol, and other products where transparency or visibility of contents is important.

Note:

PET bottles are not heat-resistant. Avoid hot filling or prolonged sun exposure.

________________________________________

🔹 2. PE (Polyethylene) Bottles

PE is divided into HDPE (High-Density) and LDPE (Low-Density), which differ slightly in softness and applications.

HDPE Characteristics:

- Opaque, relatively stiff texture

- Excellent chemical stability

- High corrosion resistance

LDPE Characteristics:

- Soft and easy to squeeze

- Good flexibility and impact resistance

Common Uses:

- Pump bottles for cleaners

- Refill packaging bottles

- Industrial chemical bottles

Suitable For Packaging:

Acidic or alkaline content, thicker cleaners, industrial solvents, etc.

________________________________________

🔹 3. PP (Polypropylene) Bottles

Characteristics:

- Heat-resistant (up to 100°C or higher)

- Stiff texture with some flexibility

- Excellent chemical resistance

- Microwave-safe (food-grade PP)

Common Uses:

- Pump and spray components

- Pharmaceutical packaging

- Food containers

Suitable For Packaging:

Products requiring hot filling or repeated use; commonly used for pump and trigger sprayer structural parts.

________________________________________

✅ How to Choose the Right Packaging Material?

Before selecting a bottle, consider the following factors:

| Consideration | Recommended Material |

| Need for transparency | PET |

| Corrosive contents | HDPE / PP |

| Heat resistance | PP |

| Squeezable usage | LDPE / HDPE |

| Use with pump/sprayer | PP parts with PET or HDPE bottles |

🏁 Conclusion

Each plastic bottle material has its own unique properties and suitable use cases. Understanding these differences can help extend your product’s shelf life and improve user experience.

If you have special requirements or are unsure which bottle to choose, our team has years of experience in packaging for cleaning products. We can provide expert material recommendations and customized solutions.

Feel free to contact us—let your product stand out, starting from the bottle!